|

1. Are Integrity™ aluminum fences safe for pool enclosures?

|

All fences in our Resort Collection™ are specifically designed to comply with the most widely accepted requirements for pool safety, known as the B.O.C.A. code. Fences in our other collections may not comply based on height and other factors. For more information, refer to our Pool Safety link or contact us directly. Local codes may vary, so you should confirm compliance with your local governing authorities even when selecting from our Resort Collection™ of pool safe fences. For other planning considerations, visit our Pool Project Advice link.

|

|

|

2. Will Integrity™ aluminum fences contain my dog?

|

Standard space between vertical pickets in our residential and pool grades is just under 4” so many small dogs can slip through. If your purpose is to create a barrier for small dogs, consider our Extreme™ vertical picket spacing, which offers any of our styles with a smaller gap between the vertical pickets. Also, you can order any style with ” puppy pickets”. Puppy pickets offer our ”Extreme™” spacing, but only on the lowest part of the fence. For larger or more aggressive dogs, you may want to consider upgrading to a commercial grade such as our Premier Collection™.

|

|

|

3. Is it difficult to install Integrity™ aluminum fencing?

|

Aluminum fencing is perhaps the most installer-friendly fencing available! Though durable, aluminum posts are not as large as say, 4×4 or even 5×5 monster posts often used for wood or vinyl fencing, so digging the holes is easier. The pre-assembled and gentle-on-the-back panels enable the project to move along efficiently. With only a short list of tools needed, you’ll be amazed at the pace of your work! Take a look at our Installation Advice link and see for yourself! Also remember that our installation consultants are always only a phone call away for all of our customers, even on weekends!

|

|

|

4. Do Integrity™ aluminum fence panels require assembly?

|

No. All Integrity™ fence panels come to you factory-assembled and ready to install! And, unlike many manufacturers, all finials and most other accessories come factory-installed as well! When you think Integrity™, you’re thinking (and installing!) right out of the box!

|

|

|

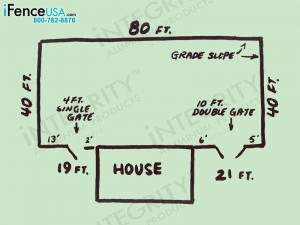

5. Can Integrity™ aluminum fences be installed on a hill or severe grade slope?

|

Yes, with some exceptions (which are noted in style specifications). Standard Integrity™ fence panels can ”rack” or adjust to conform to a grade slope, but there are limits, as noted in the specifications of each style. For moderate grade slopes, Xtra-Rack™ panels can be ordered. See style specifications for the limits of Xtra-Rack™ panels. For more severe grade slopes, we offer a Max-Rack™ feature on many styles, but we recommend you consult with one of our sales associates for the limits of our Max-Rack™ rackable panels.

|

|

|

6. Can Integrity™ aluminum fences be installed in a rounded or curved configuration?

|

Yes. As the fence panels are being installed they can be shifted directionally up to 30 degrees with ease. While the panels themselves are not rounded or bent, the cumulative effect of this slight adjustment at each post creates a rounded effect, giving your fence curve appeal! For tighter curves, order narrower panels or just cut standard panels in half and use additional line posts.

|

|

|

7. What about very sharp angles?

|

Sharp angles are not a problem when you purchase our smart adjustable mounting brackets. These brackets are available in each grade of Integrity™ fencing and are specifically designed to connect to the horizontal rail of the fence panel, making it possible to negotiate sharp angles more easily than by trying to force the horizontal rails into the punched holes of posts under such conditions. Adjustable mounting brackets can be attached to structures such as pillars, or simply attached to blank posts. In most cases, they can also be positioned to cover punched rail-receiving holes when attached to line, end, or corner posts.

|

|

|

8. How do I attach Integrity™ aluminum fences to structures such as pillars or buildings?

|

There are two ways to do this. The first is to attach the fence panel to an end post installed butted up to the structure itself. Often, when conditions do not allow below-surface installation of the post, it is secured to the structure while resting on the grade or buried slightly below grade. The alternate commonly used method is to forego the use of posts and attach the fence panel directly to the structure using rail mounting brackets. These brackets are sized to house the end of the horizontal rails of the fence panel and are available in three designs: Stationary for straight-on attachments, horizontally adjustable for attachments that enable a side-to-side swivel, and vertically adjustable for attachments that enable an up-and-down swivel.

|

|

|

9. Can Integrity™ aluminum fences be installed on a hard surface such as concrete?

|

Yes. There are two types of flange that are available for this purpose. The most durable post-to-surface attachment we offer is welded flanges for posts. Factory-welded, then powder coated, these welded flanges are ideal for mounting a post to hard surfaces such as concrete. They are sized appropriately for each type of post’s base and then welded to the base. For best results, use welded flanges when the surface grade is level or near-level. An alternative is our two-piece wedge flanges for posts. Though not as strong, they can be more versatile because they enable you to cut each post on location, which can be useful in keeping the top of the fence level when the grade below fluctuates. For a durable and versatile installation without the use of flanges at all, you may want to consider coring a hole into the concrete surface and installing your posts by re-cementing. Properly executed, this can be a very effective installation approach, but we strongly recommend you contract a professional concrete cutting company to do the coring.

|

|

|

10. Should I install my Integrity™ fence directly onto the concrete around my pool?

|

In our opinion, no. While we do appreciate the desire to put an end to grass-trimming around the base of a fence, we recommend accomplishing this goal through alternate means, such as landscaping rocks or wood chips. Integrity™ aluminum fences can be installed ”hugging” the concrete, with the posts butted up against the concrete, for a clean, attractive look. Using flanges or coring the concrete is certainly possible, but this type of installation too close to the concrete’s edge can be potentially damaging to the strength of the concrete, causing unsightly cracking. While installing further away from the concrete’s edge may prevent this type of damage, consider that you are then eating into your usable space while still paying for the unusable space! In our view, mounting to a concrete surface should only be done only when there is no other option. Take our recommendation and save yourself the unnecessary expense. For other planning considerations, visit our Pool Project Advice link.

|

|

|

11. Can Integrity™ aluminum fences be ”stepped” to negotiate a grade slope?

|

Yes. The best way to ”step” (rather than ”rack”) fencing on a grade slope is to use blank posts and rail mounting brackets. With this method, the panels on each side of the post can be staggered or ”stepped”, meaning they are attached at different points on the post causing one panel to be positioned lower than the other. Unlike rackable panels which cause the fence to follow the grade slope, ” stepping” without the use of retaining walls creates triangular gaps between the grade and the bottom of the fence next to the posts because the fence panels remain level and deviate from, rather than follow, the grade slope. These gaps are merely an aesthetic consideration unless a swimming pool is being enclosed, in which case the gaps of the stepping method are not likely to comply with pool safety codes because of the possibility that a small child could slip under the fence.

|

|

|

12. Are Integrity™ gates welded?

|

Yes. All Integrity™ aluminum gates are welded for maximum durability. After being welded, they are then powder coated. Don’t ever settle for gates that are spot welded and painted over. Sadly, this unbecoming and inferior method is used by some manufacturers.

|

|

|

13. How do Integrity™ fence panels attach to posts?

|

Integrity™ fence panels are designed with horizontal rails that slide into holes that are punched into the posts. These holes are a specific size and shape that accept the insertion of the horizontal rail of a particular grade of fence panel. This fence panel is then affixed with a screw fastener to the post. All posts that have these holes are called punched posts. There are several types of punched posts available, each with a specific use. Line posts are used to attach two panels to one post on opposite sides of the post. Corner posts are used to attach two panels to one post on adjacent sides of the post, and end posts are used to attach one panel to one post on one side of the post. Three-way posts are used occasionally to attach three panels to one post on three sides of the post. Four-way posts are rarely used but are available as a custom order post.

|

|

|

14. What is a blank post?

|

A blank post is simply a post that has no holes punched into it to receive the horizontal rail of a fence panel. When panels need to be attached to blank posts, this is accomplished using rail mounting brackets. Blank posts are often used as a gate post when a gate is installed butted up to a structure. In this case, since the gate post next to the structure will not have a fence panel attached to it, it is better to use a blank post rather than a punched post. Any size post in any wall thickness we sell can be ordered as a blank post.

|

|

|

15. How do gate posts differ from other types of posts?

|

There are typically two types of posts used to install gates, punched end posts, or blank posts. Either type can be used as a latch post or a hinge post. What determines which type is used is whether or not a fence panel will be attached to the post adjacent to the gate. Since these posts can be used in situations not involving a gate, they are technically not gate-specific. When one refers to a gate post, it is still necessary to indicate which type of post is needed. With Integrity Aluminum Products™, a gate post, regardless of its type, always comes standard with the maximum wall thickness of .125” for all 2” or 3” square posts. Don’t ever settle for less!

|

|

|

16. Can Integrity™ aluminum fences be used as railing or be installed on decks?

|

We do not sell or recommend aluminum fences for this type of application. Integrity Aluminum™ fences are not strength tested for safe use as railing when your application requires railing by code. For this use, we carry hand railing. However, aluminum fencing is often used when railing is not a code requirement, such as when a porch or deck is only inches off grade. Check with your local governing authority before using aluminum fencing on a raised deck or patio as Integrity Aluminum Products does not assume liability for improper, unintended, or illegal use of its products.

|

|

|

17. Can Integrity™ aluminum fences be customized?

|

Yes. Non-conforming conditions are common to fencing, so we offer real solutions, rather than panels and gates in the usual pre-determined heights and widths. Wider or narrower panels and gates, longer posts, special welding, altered rail positions, and much more is possible and cost effective. Whatever your requirements may be, let our skilled professionals determine feasibility and prepare a special quote for you! For more information, visit our Custom Fences link.

|

|

|

18. Can I order an Integrity™ aluminum gate in a custom width?

|

Yes. Any custom width between the minimum and maximum sizes available is possible. Prices are calculated in per-foot increments. For instance, a gate ordered wider than a standard size increment will be rounded up in price to the next size increment. The width of a gate is always defined as the width of the opening for the gate, not the actual size of the frame of the gate. Our gates are constructed with the necessary space reductions to accommodate included hinge and latch hardware. Width of opening and any modifications to included hardware must be declared at time of a gate order. Incidentally, custom gate heights are also possible. Custom heights are most often ordered when gates are purchased independent of fencing.

|

|

|

19. Do Integrity™ aluminum fences require maintenance?

|

No. Integrity™ Aluminum powder coated fences do not require maintenance. They will stay beautiful for years.

|

|

|

20. Can electronic gate operators be used with Integrity™ gates?

|

Yes, but this applies only to Ultimate™ commercial grade gates, which includes all Integrity™ Driveway Gates. Please designate that you will be installing electronic gate operators when you order a gate.

|

|

|

21. What is powder coating?

|

Powder coating is a completely dry finishing process that produces a high quality, long lasting finish twice the thickness and hardness of typical acrylic or baked enamel finishes. It is far more durable, fade resistant and scratch resistant than other coatings. For more interesting information, please visit our Powder Coating link.

|

|

|

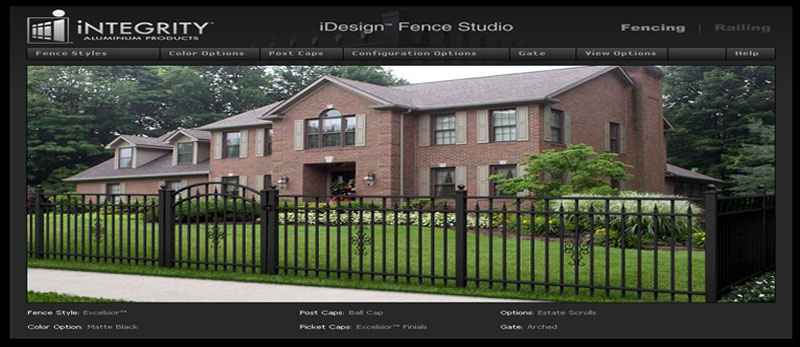

22. What colors are available?

|

Standard Integrity™ Aluminum colors are black, bronze, white, green, sandstone and beige. Most colors are available in gloss or matte finish. There is no upcharge for any of the standard colors. Custom colors are possible with certain limitations and are subject to an upcharge. Contact us for a free quote on any custom color.

|

|

|

23. What is the difference between “flush bottom” and “classic bottom”?

|

These terms refer to the position of the bottom horizontal rail of a fence panel. The vertical pickets of fence panels with a ”flush bottom” do not protrude below the bottom horizontal rail. The vertical pickets of fence panels with a ”classic bottom” protrude below the bottom horizontal rail by approximately 4” (or more, depending on the style or grade). All Integrity™ Aluminum fences are constructed with classic bottoms except for Resort Collection™ pool fences, which are all flush bottom. All fence styles are constructed as indicated in their particular specifications. Any changes are considered to be custom and must be declared at the time of order. Please keep in mind Resort Collection™ pool fences are designed to meet the widely recognized B.O.C.A. pool safety code, so modifying the bottom rail position these styles is not recommended.

|

|

|

24. Can I order Integrity™ fence products à la carte?

|

Yes. Fence panels can be ordered without gates and vice versa. Posts or post caps can be ordered independently, etc. etc. Visit our link for a complete list of our Options & Accessories. The only recommended exceptions to à la carte ordering are factory installed accessories (such as circles). In theory, all of the parts of a fence could be ordered à la carte for later assembly, but this would not be the most cost-effective way to order! Keep in mind that some features cannot be added to previously assembled panels.

|

|

|

25. How long does it take to get my Integrity™ fence?

|

Most of our products generally ship approximately two to three weeks after purchase is made and payment has been received. However, some orders can take a little longer. This may be because of the size of the order or other factors including but not limited to peak season demand, holidays, special crating, or less often painted colors. Rest assured that we make every effort to expedite all orders. Often, it is possible to expedite small supplemental (add-on) orders such as an extra post, so long as they can be shipped Fedex or USPS ground rather than by common carrier freight. For emergency situations talk to an iFence™ sales associate directly for additional priority possibilities. Our Shipping Terms link offers more information.

|

|

|

26. Should I obtain a property survey?

|

|

Obtaining a recent survey of your property lines is a good idea if you are following your perimeter with a fence. However, if a survey is not within your budget, city records of your property or the papers that accompany your mortgage loan may contain your plat map. Keep in mind that there are disclaimers on most plat maps that the measurements referenced may be ”approximate”.

|

|

|

27. Can Integrity™ fence panels be cut into a narrower width?

|

|

Yes. The horizontal SmartRail™ of a fence panel can be cut at any point to create a narrower-width panel. This is a good thing, because a fence line does not usually measure to the exact inch the total linear feet of panel material on hand. Typically, a panel needs to be cut or trimmed on site. Often, such trimming is planned ahead. For instance, a piece of a trimmed panel can be used as a filler when a gate is going to be installed inches away from the wall of a house, requiring a narrow piece of panel to fill the gap. When cutting fence panels, the horizontal SmartRail™ needs to be re-notched to fit into the punched holes of a post. A power hacksaw can make this easy! With product versatility like this, ”scrap” material is minimized. Better yet, unforeseen layout changes are usually manageable without putting the installation project on hold.

|

|

|

28. Can Integrity™ gates be cut to be narrower or shorter?

|

|

No. Gates are welded together, then powder coated, so they cannot be cut after they are made.

|

|

|

29. Do Integrity™ fence panels and/or gates include posts?

|

|

No. Panels, gates and posts are sold separately.

|

>>

>>